107 Welding Wire Feeders Starting at $940.13

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 84 - Dual Boom Feeder, NO U/I #K3330-1

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 84 - Dual Boom Feeder, NO U/I #K3330-1

Lincoln Welding and Plasma Cutting Accessories

MAXsa® 22 Feed Head #K2370-2

Lincoln Welding and Plasma Cutting Accessories

MAXsa® 22 Feed Head #K2370-2

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 25M Aluminum Case Wire Feeder #K2536-4

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 25M Aluminum Case Wire Feeder #K2536-4

Lincoln Welding and Plasma Cutting Accessories

LN-25X® w/ CrossLinc® & TVT (with Flowmeter,Tweco®) #K4267-3

Lincoln Welding and Plasma Cutting Accessories

LN-25X® w/ CrossLinc® & TVT (with Flowmeter,Tweco®) #K4267-3

Lincoln Welding and Plasma Cutting Accessories

LN-25X® Extra Torque with CrossLinc®, TVT™, No Flowmeter, Tweco® #K4267-5

Lincoln Welding and Plasma Cutting Accessories

LN-25X® Extra Torque with CrossLinc®, TVT™, No Flowmeter, Tweco® #K4267-5

Lincoln Welding and Plasma Cutting Accessories

LN-25X® Wire Feeder w/ CrossLinc®, TVT™, Flowmeter, Twistmate®/Dinse® #K4267-4

Lincoln Welding and Plasma Cutting Accessories

LN-25X® Wire Feeder w/ CrossLinc®, TVT™, Flowmeter, Twistmate®/Dinse® #K4267-4

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 25M Plastic Case Wire Feeder #K2536-5

Lincoln Welding and Plasma Cutting Accessories

Power Feed® 25M Plastic Case Wire Feeder #K2536-5

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Base Model #K2426-4

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Base Model #K2426-4

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Base Model Wire Feeder #K5282-1

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Base Model Wire Feeder #K5282-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Drive Boom One-Pak® #K5000-11

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Drive Boom One-Pak® #K5000-11

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, U/I #K5004-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, U/I #K5004-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ CE (Twist Mate™/Dinse®) #K3519-2

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ CE (Twist Mate™/Dinse®) #K3519-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Heavy Duty Wire Reel Stand #K5000-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Heavy Duty Wire Reel Stand #K5000-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Gouge Kit #K3883-4

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Gouge Kit #K3883-4

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, No Reel #K3883-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, No Reel #K3883-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, No U/I #K5004-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, No U/I #K5004-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, No Reel #K3883-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, No Reel #K3883-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Heavy Duty Wire Reel Stand #K5002-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Heavy Duty Wire Reel Stand #K5002-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Std. Dty. Reel #K3883-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Std. Dty. Reel #K3883-5

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-2 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-2

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-2 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Contactor and Gouge Stud, No Wire Reel Stand #K5000-3

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Contactor and Gouge Stud, No Wire Reel Stand #K5000-3

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Heavy Duty Reel, Gouge Kit #K3883-14

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Heavy Duty Reel, Gouge Kit #K3883-14

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Bench Model, Wire Reel Stand #K5282-2

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Bench Model, Wire Reel Stand #K5282-2

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ / Magnum® PRO Curve 300 Wire Feeder One-Pak® #K3564-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ / Magnum® PRO Curve 300 Wire Feeder One-Pak® #K3564-1

Best Wire Feeder Machines and Accessories for Your System

Shop any wire feeder you may need from Welders Supply. Our variety of Push, Pull, and Push/Pull wire feeders can complete whatever your system may need at affordable prices.

Completing or upgrading your welding system? Welders Supply Company can help find that perfect Miller wire feed that you are looking for. A variety of options and models are available to order. We carry the most popular brands and have products for the most important features that you need.

Wire feeder brands:

-ESAB

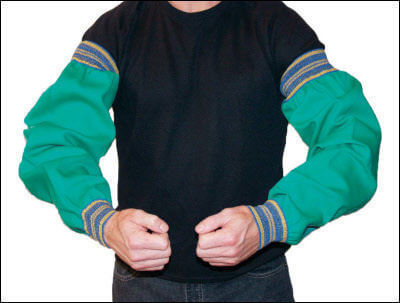

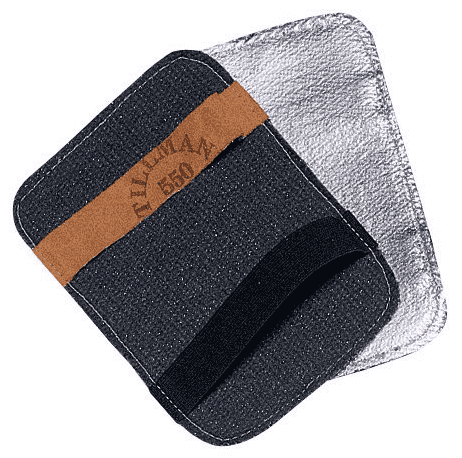

Many welders are sick of burning their hands as they attempt to hand-feed the filler metals. The flexibility and control that wire feeders provide make welding easier, safer, and cleaner. Each welding setup needs specific tools that match your welding torch, power supply, and your preferences. Our wire feeders have features appropriate for whatever your situation is.

Some features offered by different feeders:

-Extended reach for ease of use

-Remote control wire feeders

-Instant turn off To keep you and your tools safe

-Dual wire feeders options to use two different wires without switching spools

-Accurate and consistent wire speed control

Voltage sensing wire feeders vs. Constant speed wire feeders

A few defining factors separate voltage sensing from constant speed wire feeders:

- Constant speed wire feeder has a CV power source

- Voltage sensing wire feeders are used with CC or CV power sources.

- You control voltage of constant speed feeders at the power source, but control speed at the feeder.

- Voltage sensing wire feeders combined with CC power sources are controlled directly by the distance from the workpiece and the tip of the torch.