35 Best CNC Plasma Cutters Starting at $715.00

Automate your fabrication process with our industry-leading CNC plasma cutters, designed for seamless integration with tables like Langmuir, CrossFire, and Torchmate. We stock mechanized systems from Hypertherm and Thermal Dynamics featuring pre-installed CPC ports and serial interfaces for true Plug-and-Play performance. Whether you need the high-speed precision of a Powermax SYNC or a budget-friendly Razorweld for your home shop, we have the power source to match your gantry.

Thermal Dynamics

Thermal Dynamics® Cutmaster® 50+ Plasma Cutter w/ 16' Hand Torch (120/240V 1PH) #1-5000-1

1 purchased

Thermal Dynamics

Thermal Dynamics® Cutmaster® 50+ Plasma Cutter w/ 16' Hand Torch (120/240V 1PH) #1-5000-1

1 purchased

Thermal Dynamics

Cutmaster® 70+ Portable Plasma Cutter (400V 3-Phase) #1-7000-2

Thermal Dynamics

Cutmaster® 70+ Portable Plasma Cutter (400V 3-Phase) #1-7000-2

Thermal Dynamics

Cutmaster® 50+ Plasma Cutter w/ SL60 Hand Torch (400V 3-Phase) #1-5000-2

Thermal Dynamics

Cutmaster® 50+ Plasma Cutter w/ SL60 Hand Torch (400V 3-Phase) #1-5000-2

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (600V 3PH) #078617

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (600V 3PH) #078617

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (240V 3PH) #078612

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (240V 3PH) #078612

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (200/208V 3PH) #078610

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (200/208V 3PH) #078610

MAXPRO200 Plasma Cutters

MAXPRO200 Power Supply (380V 3PH) #078613

MAXPRO200 Plasma Cutters

MAXPRO200 Power Supply (380V 3PH) #078613

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (440V 3PH) #078616

MAXPRO200 Plasma Cutters

MAXPRO200 Plasma Cutter, Power Supply Only (440V 3PH) #078616

How to Choose the Right Power Source for CNC Plasma

Choosing a plasma cutter for your CNC table is different than buying one for hand cutting. In automation, "Pierce Capacity" and "Connectivity" are your most critical specs. Here is what you need to know to build your rig.

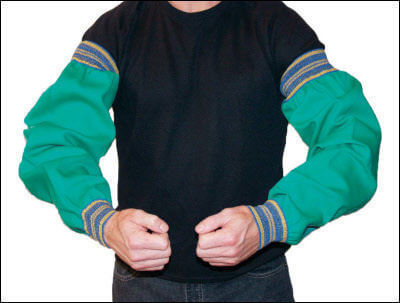

1. Mechanized vs. Handheld Torches

While you can mount a handheld torch to a gantry, a Mechanized Torch (Machine Torch) is superior for CNC applications. They feature a straight barrel utilizing a rack-and-pinion gear for precise height control and easier mounting alignment.

Tip: If you plan to use the machine for both table and manual work, look for "Combo" packages that include both torch types.

2. The "CPC Port" Factor (Connectivity)

The #1 struggle for DIY CNC builders is wiring. To avoid splicing into raw voltage lines, look for a machine with an installed CPC Port (Circular Plastic Connector).

- With CPC: Allows for "Plug-and-Play" connection to your Torch Height Controller (THC) and CNC controller. It safely accesses the voltage divider signal.

- Without CPC: Requires you to manually tap into the machine's internal wiring to get the arc voltage signal—risky and time-consuming.

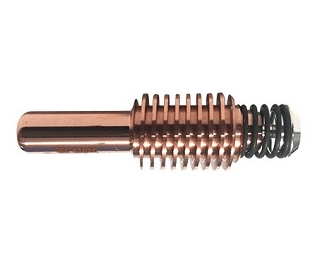

3. Pierce Capacity vs. Edge Start

Pay attention to Pierce Capacity, not just cut capacity. In CNC cutting, the torch must punch through the center of the plate (pierce) without damaging the consumables from blowback. Pierce capacity is typically 50% less than the machine's maximum edge-start capacity.

Example: A machine rated for 1" severance might only have a 1/2" CNC pierce rating.

Frequently Asked Questions About CNC Plasma

Do I need a "Serial Port" on my plasma cutter?

A Serial Port (RS-485) is generally only required for high-end industrial automation where the computer controls the amperage and gas pressure remotely (like with Hypertherm's CAM software). For most entry-level tables (Langmuir, PlasmaCAM), a standard CPC port is all you need.

Can I use a Powermax 45 XP or SYNC on a CNC table?

Yes, the Hypertherm Powermax 45 XP and SYNC models are the industry standard for light industrial CNC tables. They offer a factory-installed CPC port option and voltage divider (adjustable ratios like 50:1), making them compatible with almost every modern table controller.

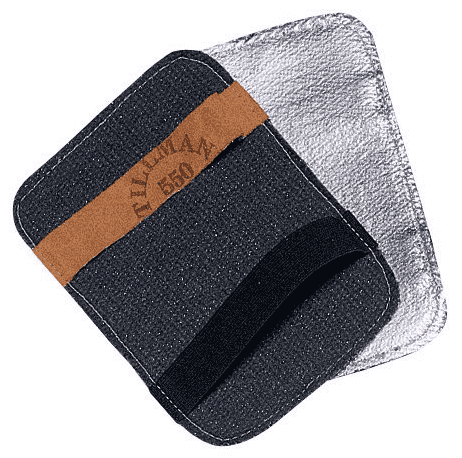

What size air compressor do I need for CNC plasma?

CNC cutting demands a 100% duty cycle from your air compressor because the torch runs continuously for long programs. You typically need a compressor that delivers 6.0 SCFM at 90 PSI or higher. Crucially, you must use an Air Dryer. Moisture in the line will rapidly destroy consumables and cause "angularity" (beveled edges) in your cuts.