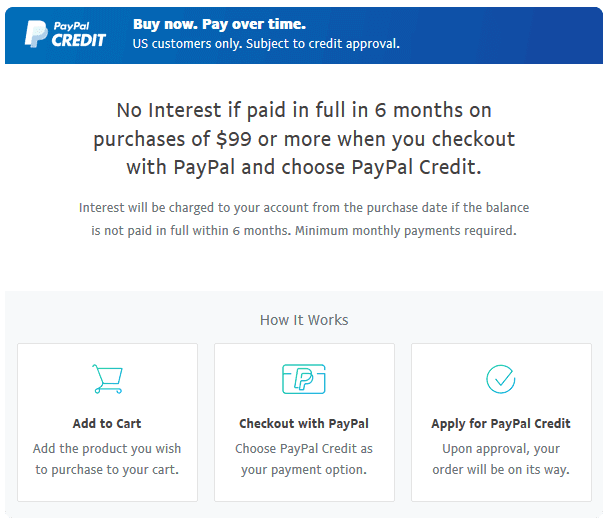

MIG Welding

MIG Welding 3-Phase

3-Phase 220V

220V 460V

460V 3-Year Power Warranty

3-Year Power Warranty

Continuum™ 350 w/Running Gear #907636001

New generation of advanced industrial welding solutions improves productivity through weld quality, ease of use and system flexibility.

All-new power source design

- Smart and powerful digital design has the fast response needed to deliver the most stable welding performance for better welding results.

- Developed as a platform to meet current and future needs with integrated expansion capabilities.

Superior Arc Performance

- Improved Accu-Pulse® provides less spatter, better arc control and less heat input &ndas; very forgiving to changes in stick-out.

- Improved MIG performance delivers consistently smooth arc starts and reduced spatter.

- Improved RMD – designed for thin materials and gap filling with very low spatter.

New Weld Processes

- Versa-Pulse™ is a fast, low-heat, low-spatter process resulting in faster travel speeds and increased productivity for semi-automated and automated welding. Typically used on thin materials up to 1/4 inch., great for gap filling on sheet metal and tube applications.

- High-Deposition MIG offers higher deposition rates than standard spray transfer — resulting in faster welding and increased productivity. Typically used for thicker material and larger welds (6 to 8 mm).

Adaptable to a Variety of Weld Cell Configurations

- Flexible user interface location (power source, feeder, remote operator interface)

- Welding Intelligence™ Solutions: Insight Core™ (standard) and Insight Centerpoint™ (optional)

- Easily add process and programs

- Wire feeder is easily configurable for standard spool sizes, 60-pound spools or bulk-feeding systems

Auto-Line™ Power Management Technology - Allows for any input voltage hookup (230–575 V) with no manual linking. Eliminates weld defects caused by dirty or unreliable power.

All-new feeder design

- Faster motor response provides the best arc starts with the least amount of spatter.

- Tru-Feed ™ Technology provides precise feeding operation for stable arc performance.

LCD Display - New user interface makes the system easy to set up and adjust with minimal training. Shows complete words, graphics and numeric values.

Easy to Set Up and Adjust with Minimal Training

- 8 program/memory buttons

- USB functionality for updates, cloning and more.

- Browser-based connection to remotely view and adjust machine parameters, configure machine settings and ability to set locks and limits.

Tool-less, Lockable Rotatable Drive

- Allows operator to rotate the drive, eliminating severe bends in the wire feeding path.

- Extends gun-liner life.

- Aids in feeding difficult wires.

MIG Welding

MIG Welding 3-Phase

3-Phase 220V

220V 460V

460V 3-Year Power Warranty

3-Year Power Warranty