16 Powermax65 SYNC Plasma Cutters Starting at $3,500.00

65A Output with 1" Cut Capacity

Hypertherm's Powermax65 SYNC uses SmartSYNC torches and consumables to eliminate setup errors and simplify inventory management. Simple, color-coded consumables last up to 5X longer, reducing operating costs. With a 1" cut capacity (1 1/4" severance), rugged durability and 200-600 1PH or 3PH power supply, the 65 SYNC handles almost any industrial application.

We’ve doubled the warranty—now 6 years—making Powermax an even stronger investment.

Best Warranty. Best Investment.

Hypertherm Powermax65 SYNC Plasma Cutters

The Powermax65 SYNC™ is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for cutting and gouging up to 20 mm (3/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC™ torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax65 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

- Easy to use

- Minimize operation costs

- Maximize performance

- Industry-leading reliability

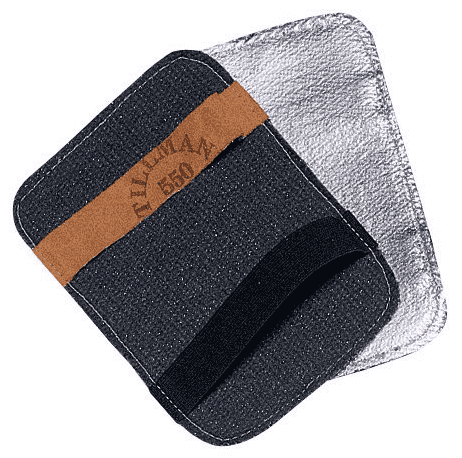

Attachment and Torch Options

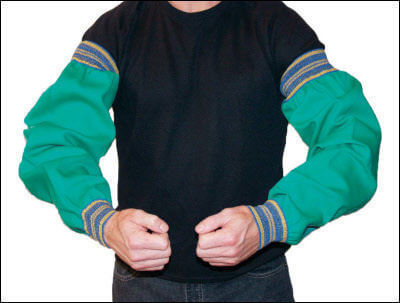

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply. Available in handheld, mechanized and robotic torch configurations.

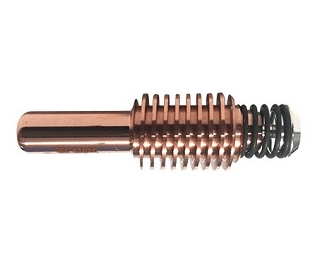

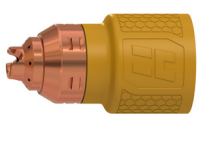

Hypertherm SmartSYNC Cartridges

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Supported Cutting Applications

- Drag cutting - For dragging the torch directly across the work piece

- Extended reach cutting - For improved visibility and accessibility when cutting in confined spaces

- Extended reach gouging - For improved visibility and accessibility when gouging in confined spaces

- Fine feature cutting - For narrow kerf width with minimal dross and heat affected zone

- Flush cutting - For cutting closer to base materials using a 45 degree

- Max control gouging - For precise metal removal, shallower gouge profiles and light metal washing

- Max removal gouging - For aggressive metal removal, deep gouge profiles, and extreme metal washing

- Mechanized cutting - For portable automation and table cutting

Unsupported Cutting Applications

- Marking - For scoring, indicating part identification, hole or weld locations

- Precision gouging - For spot and tack weld removal at very low output current (<25 A)

All Hypertherm Powermax65 SYNC Models | |||

|---|---|---|---|

| Power Supply Only | With Handheld Torch | With Machine Torch | |

| Handheld Only | |||

| CPC Port | |||

| CPC & Serial Port | |||

Compare Powermax65 vs 65 SYNC Specs | ||

|---|---|---|

Product |

Powermax65 |

Powermax65 SYNC |

| Price | Discontinued | $$$ |

| Cut Capacity | 1" | 1" |

| Output Current | 20-65A | 20-65A |

| Duty Cycle* | 50% @ 65 A, 230-600 V, 1/3-PH 40% @ 65 A, 200-208 V, 1/3-PH 100% @ 46 A, 230-600 V, 1/3-PH |

50% @ 65 A, 230 – 600 V, 1/3-PH 40% @ 65 A, 200 – 208 V, 1/3-PH 100% @ 46 A, 230 – 600 V, 1/3-PH |

| Weight | 37 lbs (20' torch) | 31 lbs (20' torch) |

| Power Supply | IGBT Inverter | IGBT Inverter |

| Compatible with SmartSYNC Consumables? | With Adapter | Yes |

| Compatible with SmartSYNC Torches? | No | Yes |