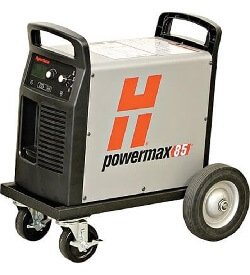

Q - What accessories and comsumables does the Powermax 65 work with?

A - The Hypertherm Powermax 65 #083372 works with all SmartSync leads, torches and cartridges 45A - 65A.

Q - How many amps does the Hypertherm Powermax 65 Sync use?

A - The Powermax 65 Sync will use between 42-70 amps, depending on the thickness of the material being cut.

Q - What torch does the Powermax 65 come with?

A - The Powermax 65 #083372 does not come with a torch.

Q - How thick will a hypertherm 65 cut?

A - The Hypertherm Powermax 65 Sync can cut 1-14" (32 mm) of material at 5 inches (125 mm) per minute.

Q - Does the Powermax 65 Sync have a warranty?

A - Yes. Hypertherm offers a 3-year power warranty.

Q - Are there any other rebates or promotions avaliable with the Powermax 65?

A - Yes, Hypertherm offers a $300 rebate for all new Powermax65 SYNC machines.

3/4" Cut Capacity

3/4" Cut Capacity

System Applications

System Applications