254 TIG Welding Machines Starting at $672.23

Precision is non-negotiable in TIG welding. Whether you are fabricating aluminum race parts, welding stainless steel piping, or working with chromoly for roll cages, you need a machine with stable arc control. We stock the industry's best TIG welders from Miller, Lincoln Electric, and ESAB, ranging from portable dual-voltage inverters to heavy-duty industrial machines. Shop below for machines featuring High-Frequency (HF) starts, AC balance control, and pulse capabilities.

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Air Cooled Package - 907911

4 purchased

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Air Cooled Package - 907911

4 purchased

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Water Cooled Package - 951000201

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Water Cooled Package - 951000201

Lincoln Welding Machines

Lincoln Electric Power MIG 220 AC/DC Multi-Process Welder (K5379-1)

3 purchased

Lincoln Welding Machines

Lincoln Electric Power MIG 220 AC/DC Multi-Process Welder (K5379-1)

3 purchased

Lincoln Welding Machines

Eagle™ 10,000 Plus Engine Driven Welder/Generator #K2343-4

5 purchased

Lincoln Welding Machines

Eagle™ 10,000 Plus Engine Driven Welder/Generator #K2343-4

5 purchased

Miller Welders

Miller Maxstar STR 210 Stick Welder – 120–480V, 907682

18 purchased

Miller Welders

Miller Maxstar STR 210 Stick Welder – 120–480V, 907682

18 purchased

How to Choose the Best TIG Welder for Your Shop

Buying a TIG machine is a significant investment. Unlike MIG welding, where voltage and wire speed are your main concerns, TIG requires you to select a machine based on the specific material you plan to weld.

1. AC/DC vs. DC Only: The Aluminum Factor

The most critical decision you will make is whether you need AC/DC capabilities or just DC.

- DC TIG (Direct Current): Ideal for steel, stainless steel, and chromoly. If you never plan to weld aluminum, a DC-only machine is a cost-effective choice that creates smooth, deep-penetrating welds on ferrous metals.

- AC/DC TIG (Alternating Current): Required for welding aluminum and magnesium. Aluminum has an oxide layer that requires the cleaning action of the AC cycle to break through. If you are a fabrication shop or automotive enthusiast, we highly recommend investing in an AC/DC unit.

2. Inverter vs. Transformer Machines

Modern inverter TIG welders (like the Miller Multimatic or Lincoln Square Wave) convert power electronically. This makes them significantly lighter, more energy-efficient, and often provides a smoother arc with more adjustability (like frequency and balance control) compared to older, heavy transformer machines.

3. Essential Features to Look For

- High-Frequency (HF) Start: Allows you to start the arc without touching the tungsten to the metal, preventing contamination. Essential for high-quality aluminum and stainless work.

- Pulse TIG: Rapidly switches between high and low amperage. This minimizes heat input, reducing warping on thin sheet metal—perfect for auto body work.

- Dual Voltage (MVP): Machines that can run on both 120V household power and 240V shop power, giving you maximum portability.

Frequently Asked Questions About TIG Welders

What kind of TIG welder do I need for aluminum?

To weld aluminum, you generally need a TIG welder with AC (Alternating Current) capability. The positive half of the AC cycle cleans the oxide layer off the aluminum, while the negative half penetrates the base metal. You cannot effectively TIG weld aluminum with a standard DC-only machine.

Can I run a TIG welder on a standard 110V outlet?

Yes, many modern inverter TIG welders offer "Dual Voltage" capability. This allows you to plug into a standard 110V/120V household outlet for lighter work (usually up to 1/8" thick steel). For thicker materials (3/16" or 1/4"), you will need to switch the plug to 220V/240V to utilize the machine's full amperage range.

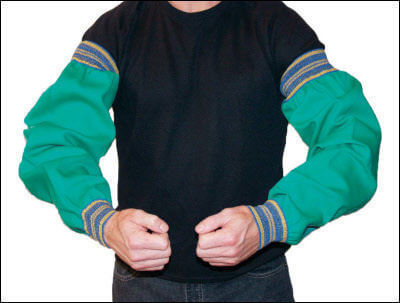

Do I need a water cooler for my TIG welder?

For hobbyists or short-run welding, an air-cooled torch is usually sufficient. However, if you are welding at high amperages (200A+) for extended periods, or welding aluminum (which reflects heat back at the torch), a water-cooler system is highly recommended to prevent the torch from overheating and to keep the operator comfortable.

What gas is best for TIG welding?

100% Argon is the standard shielding gas for TIG welding on almost all materials, including steel, stainless steel, and aluminum. Unlike MIG welding, you do not use active gases like CO2, as they will contaminate the tungsten electrode.

2026 Miller Authorized Online Partner & Distributor

We are officially recognized as a 2026 Miller Authorized Online Partner. This designation is your guarantee that every welder, helmet, and accessory you purchase is 100% authentic and backed by Miller’s full True Blue® Warranty.

Beyond just authorization, we provide the technical expertise you need to get the job done. Whether you are comparing Miller welding machine prices, hunting for specific OEM parts, or upgrading your shop’s gear, our team is trained to help you navigate the full Miller catalog. We ensure you get the right machine for your project specs—not just the one that’s on sale.

Need help choosing? Contact our Miller experts for a recommendation today.