131 Miller TIG Welders Starting at $1,849.00

Versatile TIG Performance for Industrial & Hobbyist Use

TIG (tungsten inert gas) welding is used to make precise, critical welds when joining metals such as mild steel, aluminum, or stainless steel. Like MIG welding, a shielding gas (typically argon) is required.

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Air Cooled Package - 907911

3 purchased

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Air Cooled Package - 907911

3 purchased

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Water Cooled Package - 951000201

Miller Electric

Miller Syncrowave® 212 AC/DC TIG Welder, Water Cooled Package - 951000201

Miller Welders

Miller Maxstar STR 210 Stick Welder – 120–480V, 907682

18 purchased

Miller Welders

Miller Maxstar STR 210 Stick Welder – 120–480V, 907682

18 purchased

Miller Welders

Bobcat 265 Air Pak Engine-Driven Welder w/ Battery Charger #907876

2 purchased

Miller Welders

Bobcat 265 Air Pak Engine-Driven Welder w/ Battery Charger #907876

2 purchased

Miller TIG Welding Machines at Welders Supply

Welders Supply is honored to bring you the complete line of Miller welding machines. Like us, Miller is a Wisconsin-based company committed to serving the professional welder. Starting as a one-man operation in 1929, Miller Electric has grown to become the largest manufacturer of arc welding and cutting equipment in the world.

TIG welders offer exceptional flexibility and control, allowing you to weld a lot of different metals (aluminum, stainless steel, chromoly and more) while having precise heat control—even on thin material. TIG welders are often used in motorsports and metal art fabrication.

2026 Miller Authorized Online Partner & Distributor

We are officially recognized as a 2026 Miller Authorized Online Partner. This designation is your guarantee that every welder, helmet, and accessory you purchase is 100% authentic and backed by Miller’s full True Blue® Warranty.

Beyond just authorization, we provide the technical expertise you need to get the job done. Whether you are comparing Miller welding machine prices, hunting for specific OEM parts, or upgrading your shop’s gear, our team is trained to help you navigate the full Miller catalog. We ensure you get the right machine for your project specs—not just the one that’s on sale.

Need help choosing? Contact our Miller experts for a recommendation today.

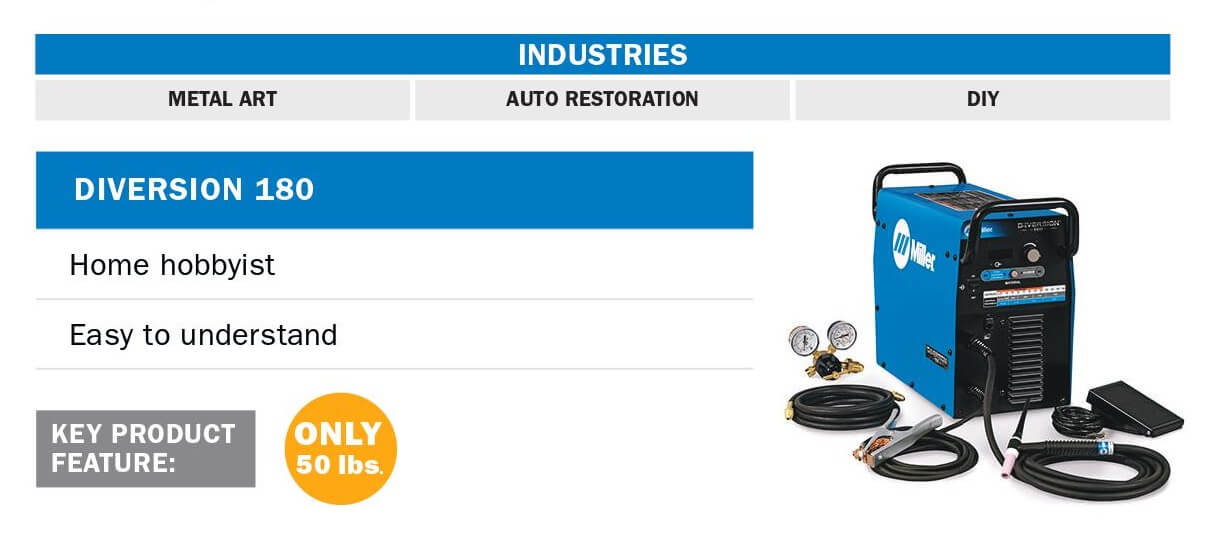

Diversion™ Series

For the personal user who wants to achieve basic operations with an easy-to-understand machine.

Designed for the hobbyist, these simple, high-performance TIG welders make welding easy, fun and affordable.

- Incredibly affordable

- Easy set-up and operation

- All-in-one packages

Best Seller: Miller Diversion 180 AC/DC TIG Welder (120/240V) #907627

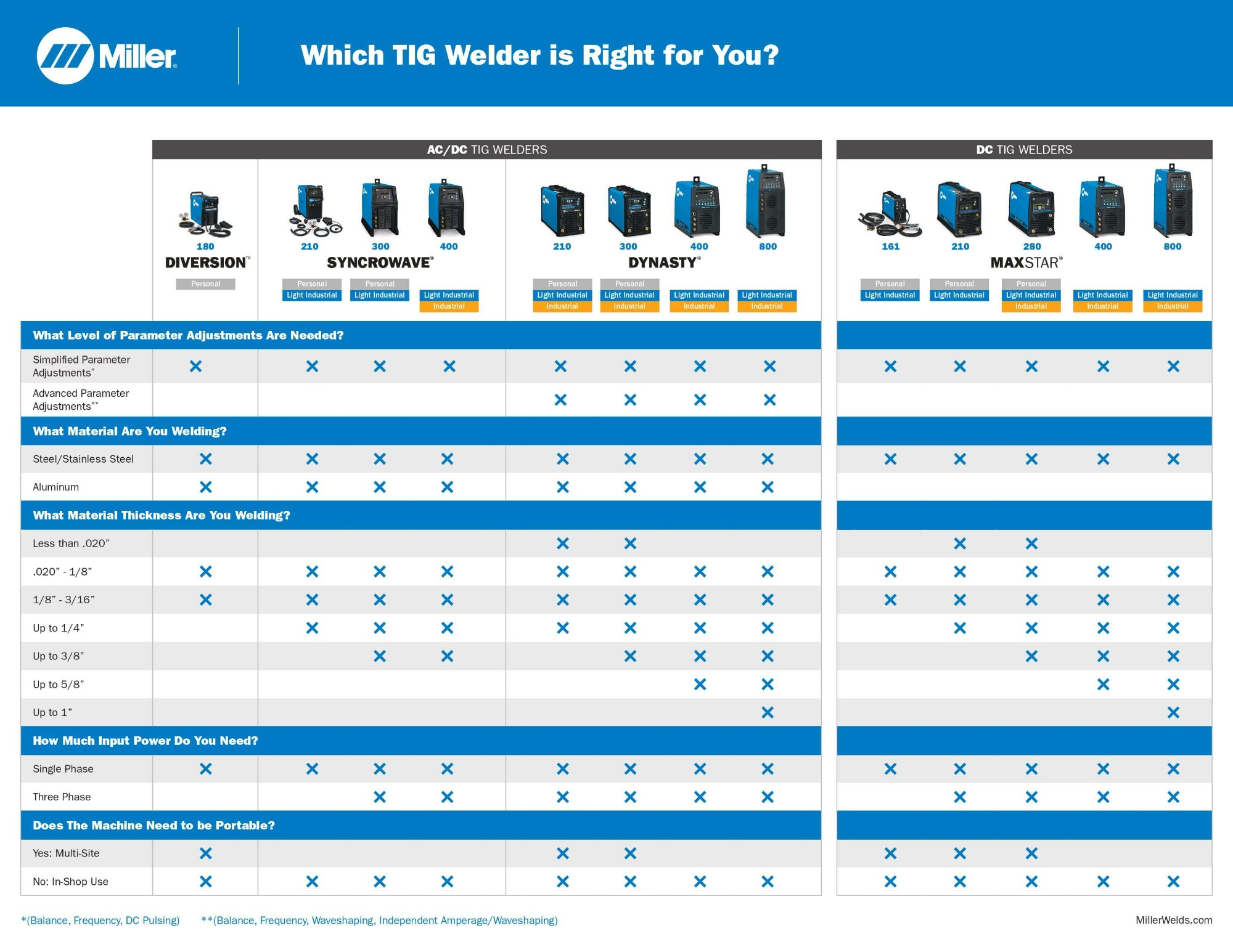

Dynasty® Series

Provides precision fabrication with ultimate versatility on all materials including aluminum for both shop and portable applications.

With a compact design and superior arc performance and control, these TIG welders help increase productivity and improve weld quality while lowering installation and operating costs.

- Advanced AC/DC TIG/STICK technology for all metals

- Optimum arc & puddle control

- Improved efficiency

- Compact, easily transported design

Best Seller: Miller Dynasty® 800 Wireless Foot Control Complete - 951000008

Maxstar® Series

From thin tube and MRO to large pipe and tank fabrication, this family of products is ideal for steel and stainless steel applications.

Advanced inverter technology combines superior arc performance and control for better weld quality and higher productivity, as well as lower start-up and operating costs.

- Most reliable DC TIG/STICK solutions in the welding industry

- Enhanced arc control

- Lower operating costs

- Compact, mobile designs

Best Seller: Miller Maxstar STR 210 120-480 V #907682

Syncrowave® Series TIG Welders

Designed for light to heavy manufacturing on all materials including aluminum for general applications.

Miller set the standard for TIG welding more than 35 years ago with the Syncrowave Series. Today, Miller expands the capabilities of these welders with wireless remote controls. Besides eliminating clutter and cord tangles (and the risks of cord failure), these controls extend your operating range without the need for cord extensions.

- Weld steel & aluminum up to 3/8”

- Single-phase or three-phase

- Simplified parameter adjustments

Best Seller: Miller Syncrowave 210 TIG/MIG Package #951684

Miller TIG Welder FAQs

What's the best Miller TIG welder for beginners and hobbyists?

Miller Diversion TIG welders are ideal for personal use. These beginner TIG welders were designed with hobbyists in mind, featuring an intuitive user interface and the ability to plug into standard 120V or higher-voltage 240V power supplies. At only 50 lbs, Diversion is lightweight enough to move around on your own.

What's the best Miller TIG welder for small shops?

For small shops, Miller Maxstar TIG welders are a compelling choice due to their ideal combination of footprint, functionality, and price. They offer industry-leading duty cycles, allowing for extended use on various materials up to ½ inch thick. Maxstar TIG welders boast superior arc control for precise welds on thin materials, a critical factor for small shops working on intricate parts.

What's the best Miller TIG welder for fabrication?

Miller Dynasty machines are the best TIG welders for fabrication due to their high amperage range of 1 to 280 amps and advanced AC/DC capabilities, offering superior precision and control for diverse metals including aluminum and stainless steel. Featuring Auto-Line™ technology for 120V-480V input and advanced waveform control, they deliver consistent, high-quality welds essential for complex fabrication projects. Their lightweight, portable design ensures easy mobility, enhancing productivity in fabrication shops.

What's the best Miller TIG welder for maintenance, repair and operations (MRO)?

Miller Maxstar machines excel in MRO environments due to their durability, reliability, and advanced features. They boast a wide output range for handling thin sheet metal up to thick weldments, a key factor in MRO for repair and maintenance of diverse equipment. Maxstar TIG welders offer superior pulse control for precise heat input, minimizing distortion on delicate components prevalent in MRO applications.

What's the best Miller TIG welder for steel/stainless steel?

Miller Maxstar machines excel as TIG welders for steel and stainless steel welding due to their precise amperage control up to 280 amps and advanced DC welding capabilities. With Auto-Line™ technology supporting 120V-480V input, they ensure consistent arc stability and penetration, crucial for high-quality welds on steel alloys. Their lightweight design and robust construction enhance mobility and durability in industrial environments, maximizing efficiency and performance in steel fabrication and repair tasks.

What's the best Miller TIG welder for aluminum?

Miller Syncrowave and Dynasty machines are the best TIG welders for aluminum welding due to their advanced AC waveforms and precise amperage control, ranging from 1 to 280 amps. These welders feature Auto-Line™ technology for 120V-480V input, ensuring stable arc performance and high-quality welds on aluminum. Their inverter technology provides superior energy efficiency and portability, making them ideal for both shop and field applications.

Related Categories

- Welding Machines

- TIG Welding Machines

- Miller Welding Machines

- Miller Multi-Process Welding Machines

- TIG Welding Accessories

- TIG Welding Torches

- TIG Tungsten Electrodes

- TIG Welding Helmets

- TIG Welding Gloves