Q - Does this have a dual gas port?

A - Yes.

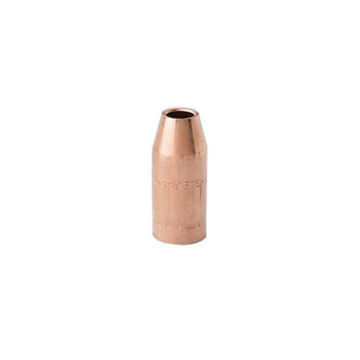

Q - What consumables kits does Miller have for this?

A - The Miller Acculock S .035 kit (#1880278) and the Acculock S .045 Kit (#1880279) will both work with the Miller MDX 250 MIG gun.

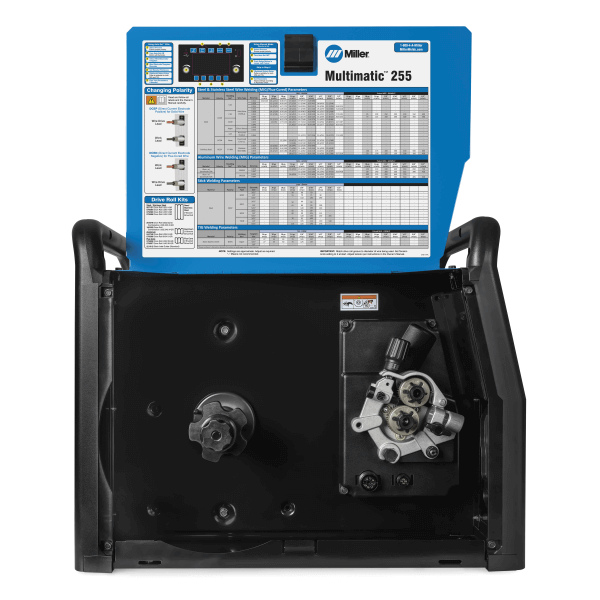

Q - Can you TIG weld aluminum with the Miller Multimatic 255?

A - Yes. However, the Multimatic 255 is ideal for aluminum MIG welding.

Q - What max thickness is it rated for?

A - The Millermatic 255 is able to weld metals up to ½” thick with an output of 230 Amps and 25.5 V at 60% duty cycle.

Q - Can I run a Miller Multimatic 255 with my 50 Amp breaker?

A - Yes.

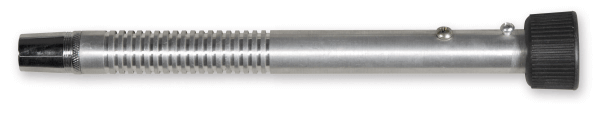

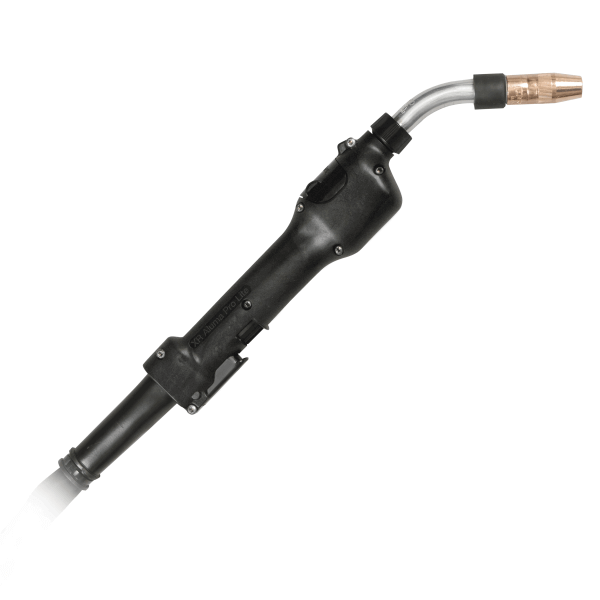

MDX 250 MIG Gun

MDX 250 MIG Gun TIG Kit

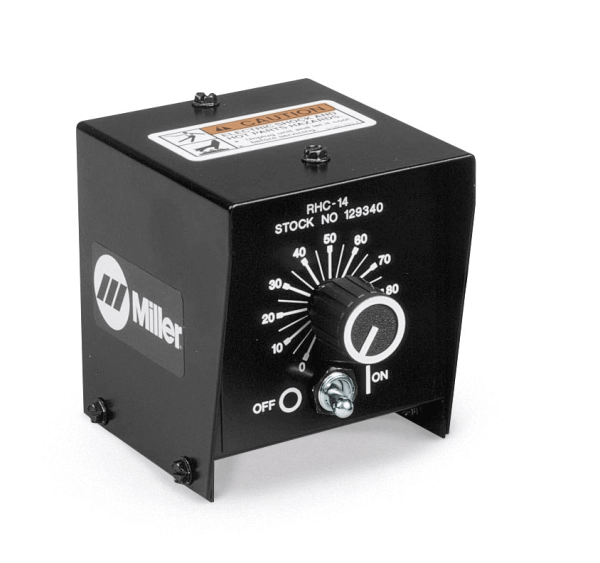

TIG Kit Single Phase Input

Single Phase Input Lightweight & Portable

Lightweight & Portable 3-Year Power Warranty

3-Year Power Warranty