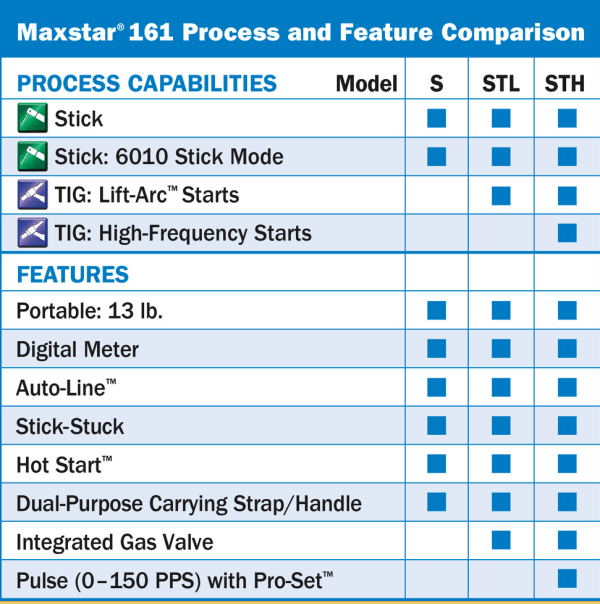

Stick Welding

Stick Welding Pulsed TIG Welding

Pulsed TIG Welding 120–240 V, 1-PH

120–240 V, 1-PH Weights Only 13 lbs

Weights Only 13 lbs 3 Year Warranty

3 Year Warranty

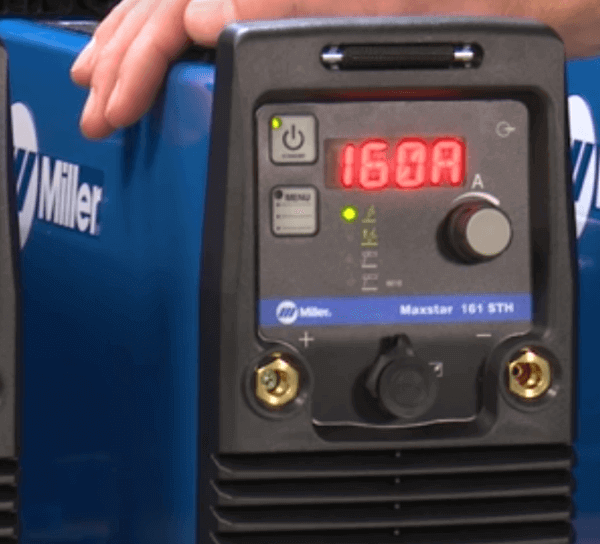

Miller Maxstar® 161 STH #907711001 120-240 V, X-Case, Contractor Package w/ Fingertip Control Included

Miller Welding Supplies Offer High Quality TIG Welds

Welders Supply is your industry leading, one-stop-shop for all of your essential welding gear and accessories. We carry a full line of Miller TIG welding supplies, and our large selection of available Maxstar 161 welding packages give our clients the opportunity to choose a welding setup that is best for them.

Miller Maxstar 161 #907711001 setup includes:

- Maxstar 161 STH

- 6.5 ft. (2 m.) primary cords for 120 V and 240 V

- 13 ft. (4m.) stick electrode holder with 25 mm. Dinse-style connector

- 10 ft. (3m.) work clamp with 25mm. Dinse-style connector

- 12.5 ft. (3.8m) Weldcraft A-150 TIG torch with 25mm. Dinse-style connector

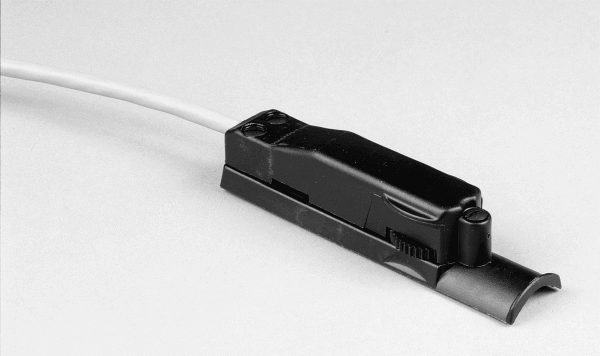

- RCCS-6M remote fingertip control

- Adjustable handle/shoulder strap

- Regulator/flow gauge and gas hose

- AK2C accessory kit

- Protective Miller X0Case

Our impressive inventory of Miller welding equipment offers both dependability and efficiency all in one affordable TIG welding machine. Here at Welder’s supply it is our goal to offer all of our clients a customer service experience light-years ahead of our closest competitors.

Discount Miller Welders for Sale

Our Miller TIG welding packages are some of the most affordable welding options currently on the market. The 161 STH is unique in the sense that it can connect to standard 120V and 240V receptacles with no additional tools or attachments. Perfect for welding stainless steel, because the Maxstar 161 STH has adjustable heat settings, it can easily weld thin metals that are usually prone to warping. In addition, this welding setup has no need for a bulky gas valve, giving the welder more control over their new TIG welding torch.

Other Versions:

- 907711 - Maxstar 161 STH 120 - 240V

Rebate Redemption

How To Submit Your Build with Blue™ Rebate Request

- Purchase a qualifying product.

- Get an electronic copy of your invoice or receipt showing the purchase of at least one of the eligible products shown below.

- Locate the serial number of each product.

- For the Additional Products rebate, circle each additional item and price paid on your invoice or receipt.

- Submit your rebate request.

30-Day Submission Deadline

Rebate claims must be submitted within 30 days of purchase date.

Submit or track rebate

Stick Welding

Stick Welding Pulsed

Pulsed 120–240 V, 1-PH

120–240 V, 1-PH Weights Only 13 lbs

Weights Only 13 lbs 3 Year Warranty

3 Year Warranty