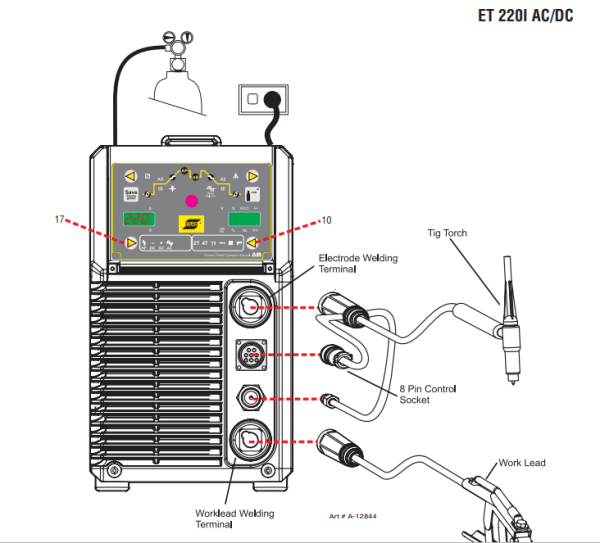

ESAB ET 220i AC/DC HF TIG Package #W1009301

The ET 220i AC/DC offers

- high output

- full digital control

- AC/DC

- Stick/Liftarc TIG/HF TIG

- Inverter power supply with expanded input voltage capabilities

The ET 220i is designed for precision TIG and Stick welding of all weldable materials. Square wave output combined with advanced balance and cleaning features deliver unbeatable welding performance. This extends tungsten life on aluminum and magnesium alloys without the need for continuous high frequency.

FEATURES:

- Embedded microprocessor with digital controls

- HF TIG and Liftarc TIG start with rapid pulse output

- Tiptronic memory functions

- Robust aluminum metal case

- High-frequency start, Liftarc TIG start, automatic downslope, pulse, repeat (latch) function, memory function and automatic gas management

INCLUDES:

- 200 amp air-cooled TIG torch with fingertip control and accessories

- Power Source

- Remote foot control

- Ground cable and clamp

- Lead cable and electrode holder

- Gas hose

- Flowmeter/Regulator

- Operator’s manual and set-up DVD

- Primary power cable

- Dinse plugs

This product replaces these legacy models:

- Thermal Arc Fabricator 181i 230Volt Mig/Tig/Stick Machine #W1003181

- Thermal Arc Fabricator 252i Multi-Process Welder (208–230V 1PH) #W1004401

- ET 186i AC/DC Welder w/ Foot Pedal #W1006303

- Fabricator 3-in-1 141i MP Integrated Welding Pkg #W1003142

- ET 186i AC/DC Stick/TIG Kit/Reg/Torch Ct. #W1006301

- MiniArc 161LTS MIG Welder w/ Case (115/230V 1PH) #558102202

| Power source weight without power cable, lb. (kg) | 29.5 (13.4) |

| Power source dimensions, L x W x H, in. (mm) | 18 x 7.25 x 13 (483 x 185 x 326) |

| Standards | CSA E60974-1, ANSI/IEC 60974-1 |

| Number of phases | 1/3 |

| Supply voltage, VAC – 1/3 ph | 208-230/460 +/-15% |

| Supply frequency, Hz | 50/60 |

| Welding current range (Stick), A – 1 ph | 10 – 150 |

| Welding current range (Stick), A – 3 ph | 10 – 170 |

| Welding current range (TIG), A – 1 ph | 5 – 200 |

| Welding current range (TIG), A – 3 ph | 5 – 220 |

| Effective input current (I1eff), A (V) – 1 ph | 37.3 (208) 33.7 (230) |

| Effective input current (I1eff), A (V) – 3 ph | 16.8 (208) 15.2 (230) 8.2 (460) |

| Maximum input current (I1max), A (V) – 1 ph | 37.3 (208) 33.7 (230) 18.1 (460) |

| Maximum input current (I1max), A (V) – 3 ph | 24.5 (208) 22.1 (230) 11.9 (460) |

| Generator requirement, kW (kVA @ PF) | 13 (16 @ 0.8) |

| Stick (SMAW), A @ V (phase) | 150 @ 40% 26 (1) 170 @ 40% 26.8 (3) |

| Welding output 40ºC (104ºF), 10 min. A @ V (phase) | 140 @ 60% 25.6 (1/3) |

| TIG (GTAW), A @ V (phase) | 200 @ 45% 18.8 (1) 220 @ 40% 18.8 (3) |

| Welding output 40ºC (104ºF), 10 min. A @ V (phase) | 180 @ 60% 17.2 (1) 160 @ 100% 16.4 (3) |

| Open circuit voltage, (VRD active), V | <113 |

SHIPPING DIMENSIONS |

|

| Height: | 13.00 Inches |

| Width: | 7.25 Inches |

| Length: | 18.00 Inches |

| Weight: | 29 Lb(s) 8 Oz |

Accessories

Consumables

Product Questions and Answers

How to Use Inverter Power Supply:

- Set Voltage Level.

Set desired voltage level using the knob.

- Set Current Limit.

Set a current limit desired to keep your welding safe but effective.

- Plug-in Ports.

Use standard 4 mm banana plugs in the input and output ports.

- Turn on Power Supply.

Using the power switch turn on the power supply and use your inverter power supply to your needs.

Single Phase

Single Phase Three Phase

Three Phase 3-Year Power Warranty

3-Year Power Warranty