3767 Welding Equipment & Supplies Starting at $1.05

Miller Welders

Millermatic 211 PRO MIG Welder – 120/240V, 15-ft Gun #907839

29 purchased

Miller Welders

Millermatic 211 PRO MIG Welder – 120/240V, 15-ft Gun #907839

29 purchased

Miller Welders

Miller Millermatic® 211 PRO MIG Welder with Running Gear & Cylinder Rack - 951000073

6 purchased

Miller Welders

Miller Millermatic® 211 PRO MIG Welder with Running Gear & Cylinder Rack - 951000073

6 purchased

Our more popular welding equipment include:

- Millermatic 211 Auto-Set Mig Welder +FREE gloves

- Millermatic 252 208/230 Volt Wire Welder +free Helmet

- Millermatic 212 Auto-Set 220 Volt Wire Welder

- Millermatic 211 Auto-Set/Small Cart 110/220 Volt Mig Welder

- Hypertherm Powermax 30xp Plasma System NEW MODEL In STOCK!

- Miller Diversion 180AC/DC Tig Welding Package

- Miller Multimatic 220 AC/DC Multiprocess welder #907757

Best Welding Products and Supplies, Lowest Online Prices, Finest Customer Service

Professional and hobbyist welders know Welders Supply is the online source for the best welding products and supplies at the lowest prices. We also have the best customer service in the business, thanks to reps who actually know the welding profession and can delve into the details on products you have questions about.

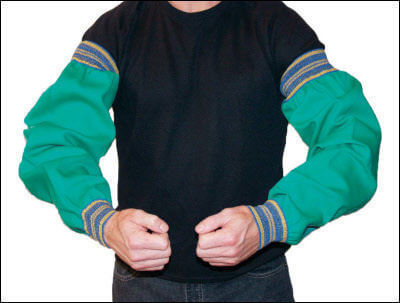

Whatever you’re looking for, chances are we have it. Welding machines, plasma cutters, helmets, safety apparel—we’ve got it all. The products we offer at Welders Supply represent the best in the industry, from top manufacturers like Miller, Hypertherm, 3M, Victor and Thermal-Arc. If we wouldn’t use it ourselves, we don’t carry it.

Quality products, low prices and great customer service are reasons enough to make Welders Supply your go-to source for all things welding, but here are a few more reasons:

FREE SHIPPING – Welding equipment can take a bite out of any budget. To take some of the sting out of your purchase, every order over $300 ships free. The offer stands for our used equipment and specials, too. What a great way to make a good deal even better!

IN STOCK – How many times have you been ready to buy a piece of equipment, only to find it’s on order? This rarely ever happens at Welders Supply. Our huge inventory all but guarantees we have what you want when you want it.

NEW PRODUCTS – You’ll see “New Product” a lot at Welders Supply. We’re constantly on the lookout for new products to make your work easier, safer and more profitable. When we find them, we get them in stock--usually before anyone else.

SPECIAL OFFERS – Welders Supply lights up this website often with terrific special offers. These aren’t “throw away” promotions for stuff we want to get rid of. They’re some of our hottest sellers.

USED WELDERS AND EQUIPMENT – We have a constantly rotating stock of used welders and welding equipment. It’s all been checked over and, when necessary, reconditioned. You can get a killer deal, but you’ve got to check our Used Welders and Equipment page on a regular basis because our used inventory moves fast.

CLOSEOUTS – There are always new products coming out. When they do, we mark down the older models. If you don’t need the latest and the greatest, you can score some really good deals on these closeouts. Don’t dawdle, though. These deals get snapped up fast.

The Best Welding Brands in the Business

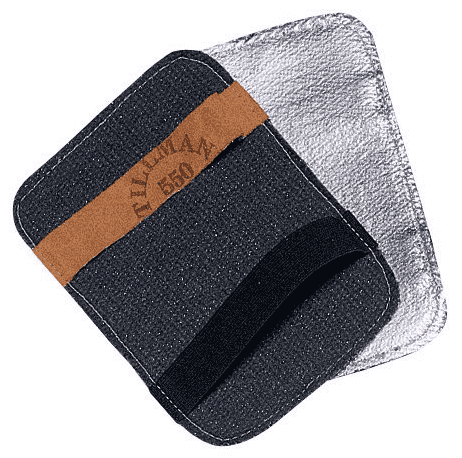

Hypertherm, Victor Technologies, Miller, Strong Hand, Weldcote, Metabo, Speedglas and J Tillman…the list goes on and on. Jackson, Sellstrom, Metalpro, Tweco, Irwin, Kromer…if you have a couple hours, we’ll keep going. Point is, the products we carry are all top quality from the best in the industry.

Is There Anything Welders Supply Company Doesn’t Have?

Honestly, if it has anything to do with welding there’s about a 99.89% chance we have it. In stock. Ready to go…and at the lowest price you’ll find anywhere.

Here’s a rundown of the products we carry:

- Abrasives

- Apparel & Clothing

- Clamps, Hand Tools, Work Benches

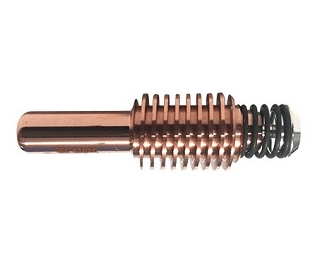

- Filler Metals

- Gas Welding & Cutting Equipment

- Gases

- Plasma Cutting Machines

- Power Tools

- Safety Equipment

- Tech College Favorites

- Welding Machines

Looking for the Lowest Price?

There’s no need to scour the Internet looking for the best price on welding equipment. No one offers better online pricing than Welders Supply. If you do find a lower price, we want to know about it. Chances are we’ll not only match, but beat it.